“Ductile” is not a word you come across very often. It means flexible, and it’s written in the federal register as a result of the Natural Gas Pipeline Safety Act of 1968, which required the Department of Transportation (DOT) to develop and enforce minimum safety regulations for the transportation of gases by pipeline. Those regulations became effective in 1970.

For more than half a century there’s been a law on the books that says pipelines must have a protective external coating that is “sufficiently ductile to resist cracking” in order to protect the pipe from external corrosion. The protective external coating that has been widely used for many years now is a green-colored fusion-bonded epoxy (FBE). It is applied via a fairly elaborate process which can be seen here in a two-minute video. The pipe lies flat while the coating is applied.

But before those sections of pipe finally come to rest in a ditch, they will be lifted many times over a period of months or years. Each time they’re lifted the pipe will flex, which is why the coating must be “sufficiently ductile” to also flex. If it’s not sufficiently ductile, the coating will crack. Once the coating has cracked it can’t uncrack and a passageway will have opened up for moisture to get to the steel pipe and begin corroding it. Corrosion could lead to disastrous, even catastrophic consequences if a leak occurs.

After a 2010 pipeline explosion and fire in San Bruno, California, killed eight people, injured more than 60 and destroyed or damaged more than 100 homes, DOT’s Pipeline and Hazardous Material Safety Administration (PHMSA) began a review of pipeline regulations, which lasted for more than a decade. In August 2022, PHMSA finalized new rules that take effect in May 2023. Nowhere in those new rules has PHMSA addressed a serious pipe-coating problem that experts have known about for years and that’s been the subject of great reporting, as pointed out by climate activist Bill McKibben.

Way back in 2004, the National Association of Pipe Coating Applicators (NAPCA) put out an eight-page bulletin which stated, at the very beginning, that FBE-coated pipe should not be stored above ground for more than six months without protection from the sun. The warning is stated again in a disclaimer at the very end of the bulletin.

As the years rolled on, it became increasingly clear that climate science was warning against building new fossil fuel pipelines. Pipeline projects started running into resistance and took much longer to get built, if they got built at all. Pipe for Keystone XL (KXL) was manufactured and coated from 2009-11. Thankfully, that pipeline never got built. But in 2018, when Canadian TC Energy was still hoping KXL might get built on former President Donald Trump’s watch, testing was done on the corrosion-proof FBE coating that had been sitting out in the sun all those years.

Long after NAPCA’s six-month window had passed, a whitewash coating was applied to the KXL pipe in a half-assed attempt to protect the FBE coating from the sun. But they didn’t even apply the whitewash to the entire length of the pipe, leaving a few feet on each end without whitewash so as not to cover up stenciling and other markings. That would be like going to the beach and applying sunscreen from your ankles to your neck, lying out in the sun all day and then wondering why your feet and face got so sunburned, or, more to the point, doing it day after day, month after month, year after year, and wondering how you got skin cancer.

The results of the testing were written up in an important article that appeared on page 16 of the January/February 2020 issue of Corrosion Management, a publication of the Institute of Corrosion. TC Energy had a hand in writing the article… and it shows. It’s basically an attempt at greenwashing whitewashing. They were trying to show that the FBE corrosion-proof coating would be just fine sitting out in the sun for years as long as it was whitewashed. The article states that overall the test results of the whitewashed pipe proved excellent and that the whitewashed FBE coating was still totally fit for purpose.

But that’s not what the study showed. It said that even whitewashed FBE coating demonstrated a “serious deterioration in its flexibility performance.” It said the flexibility tests on all the whitewashed pipe were “deemed failures,” and that the flexibility of the FBE had deteriorated “to the point where the coating was no longer acceptable.” All the flexibility tests resulted in “cracking within the coating.” So how does this measure up to the DOT/PHMSA rule that says the external protective coating has to be “sufficiently ductile to resist cracking”? Ductile means flexible. Cracking means cracking.

As clear as this article and study were about the inability of whitewash to protect FBE coating from losing its critical flexibility, they were even more damning regarding what happens to FBE coating if it never even gets whitewashed at all, which is the case with a lot of pipe that has sat out exposed to the sun for years awaiting burial. That’s true for much of the pipe for the Mountain Valley Pipeline (MVP), which is designed to operate with pressures as high as 1,480 pounds per square inch (psi). The exploding pipeline in San Bruno had a maximum operating pressure of 375 psi, less than a quarter of MVP’s pressure.

In describing the non-whitewashed FBE coating the Corrosion Management article used descriptions such as “completely failed to retain original properties and attributes,” “total failures” and “no longer fit for purpose.”

In the most recent available Google Earth images, thousands of sections of the studied KXL pipe still sit in a field in Gascoyne, North Dakota. A video posted to Facebook by the Ní Btháska Stand collective shows long trainloads of KXL pipe arriving in David City, Nebraska, in May 2020.

What will happen to all that pipe that got sunburned for years? If you think this defective coating problem is something that can’t be fixed in the field, then you agree with a KXL manager, Doug Brunning, who spoke at a 2018 oil and gas forum in Canada. He said that pipe with defective coating would have to be shipped back to the plant for stripping, cleaning and re-coating. Imagine how difficult, expensive and time consuming that would be.

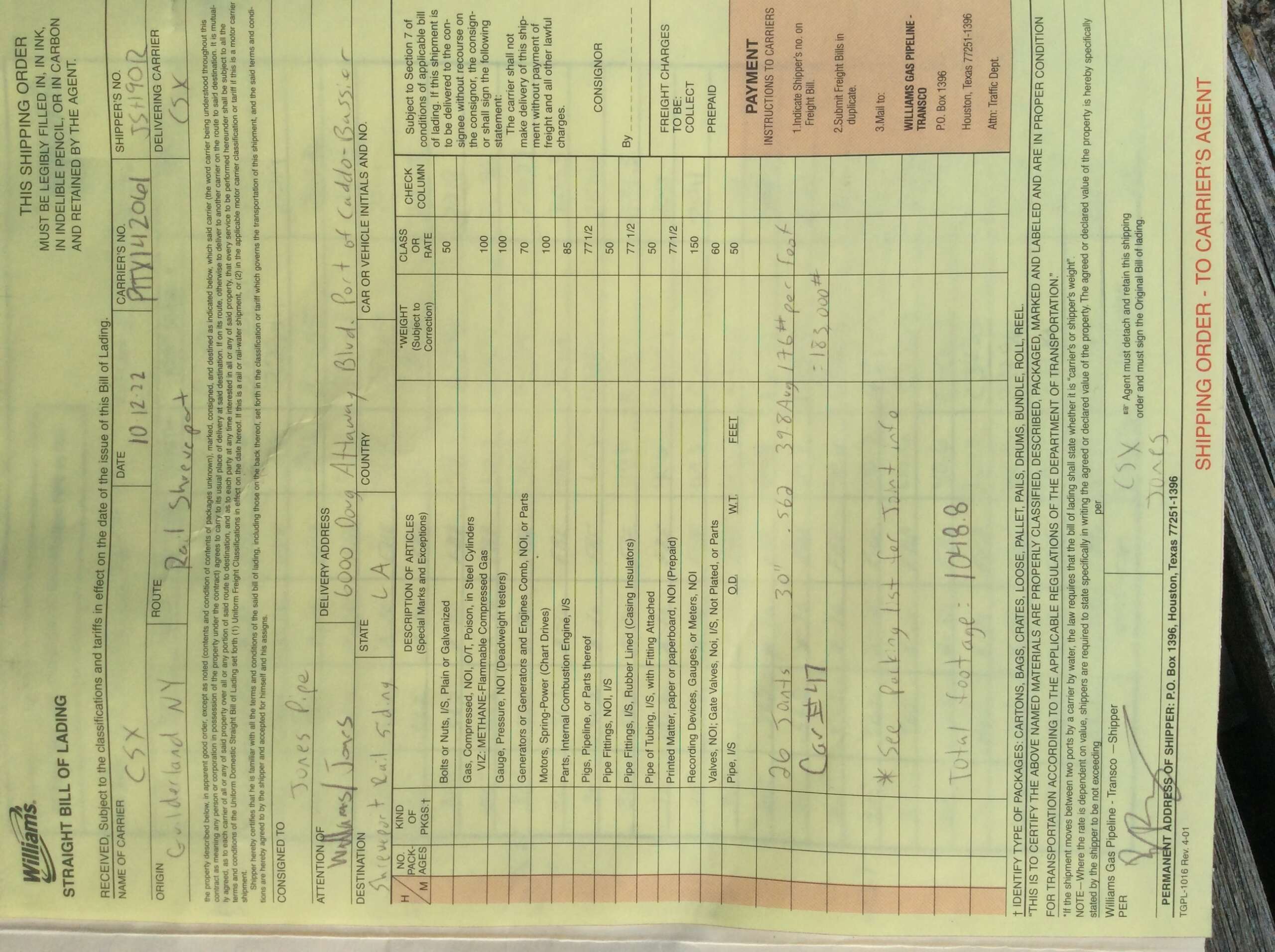

I first learned about this coating problem through Stop the Pipeline, a relatively small organization that was successful in stopping the 125-mile Constitution Pipeline in New York. All the pipe for that pipeline had been delivered to a huge industrial park not far from Albany, New York. After the pipeline was stopped, I continued to keep an eye on all that stockpiled 30-inch pipe. Every time I took my mother to the eye doctor, I’d swing by to make sure it was still there.

Last summer, I could see from a distance that some kind of machine was lifting and swinging pipe around. So, I made my way in and found numerous trucks loaded with pipe. Drivers told me they were going to various locations. One driver said he was headed to Merrillville, Indiana. Another said he was headed nearby to Schererville, Indiana. A third driver was going to Fairless Hills, Pennsylvania, and he thought some pipe might be going to Florida. A fourth was on his way to Port Wentworth, Georgia, which has two 30-inch pipelines carrying vaporized liquefied fracked gas between it and nearby Elba Island.

But most of the pipe was loaded onto Dun Transportation trucks that were going to a pipe yard just down the road from Pocono Raceway in Pennsylvania. I visited recently and can verify that some Constitution pipe is indeed there. Williams, the same company that wanted to build Constitution, has now bought the pipe back from the company they sold it to after Constitution died. The pipe was manufactured and coated in 2013-14 and has been exposed to the sun ever since.

Williams plans to use the pipe for a 22-mile pipeline that’s part of its Regional Energy Access Expansion (REAE) project. The proposed pipeline will go under two interstates, I-476 and I-81; under the Susquehanna River, a drinking source for millions; through heavily congested business and residential areas on each side of the river; and within the blast zone of an elementary school in Wyoming, Pennsylvania, which this Williams map has incorrectly labeled as a high school.

It’s hard to look at Williams’s map and understand how this pipeline is an expansion and not a new pipeline. The proposed REAE pipeline and the existing Transco pipeline do not follow the same path except for very short sections.

Some of the discounted pipe that Williams bought back was also shipped south by rail for use in its Louisiana Energy Gateway 2.0 project. In an article on ShaleDirectories.com, one of the company’s executives said the quiet part out loud: “Rising costs for steel and labor have also presented a challenge for midstream companies contemplating new pipelines, but executives said that steps have been taken to mitigate some of those costs. COO Michael Dunn said that Williams had been able to source surplus steel from cancelled projects to utilize in the Louisiana Energy Gateway project, which will help keep costs down amid the current inflationary environment.” Surplus steel is industry-speak for old pipe with defective coating.

That same article reported that, “Expansion projects have surged in popularity in recent years, as midstream operators seek to increase capacity without having to navigate an increasingly tough permitting environment for newbuild pipelines.” Hence, the new REAE pipeline, that will be built with old pipe covered with defective coating, being dubbed an “expansion” project.

I shudder to think how my generation will be remembered if we don’t stop fossil fuel expansion soon. If we don’t care what kind of a world we’re leaving for those who come after us, then I guess it’s no surprise that we don’t care if pipelines corrode prematurely and leak or explode. Because the biggest problem with new fossil fuel pipelines isn’t that their corrosion-proof coating is defective; it’s that they are, well, new fossil fuel pipelines… intended to keep operating for decades as the climate crisis accelerates.

But there may be some hope in that word: “ductile.” It’s long past time for government to begin truly enforcing the safety regulations already on the books, and perhaps environmental lawyers and organized citizens can use that word to try and stop some of these dangerous, fossil-foolish pipelines.

Join us in defending the truth before it’s too late

The future of independent journalism is uncertain, and the consequences of losing it are too grave to ignore. To ensure Truthout remains safe, strong, and free, we need to raise $27,000 in the next 24 hours. Every dollar raised goes directly toward the costs of producing news you can trust.

Please give what you can — because by supporting us with a tax-deductible donation, you’re not just preserving a source of news, you’re helping to safeguard what’s left of our democracy.